A nameplate can be engraved with the name of a person, the contents of a room, the address of a building, instructions and many other kinds of information. They can also be mounted on products and labeled with warning information or directions. Read More…

Etched Metal Company takes pride in our expertise and precision in crafting exceptional name plates. With over 80 years of collective experience, we have mastered the arts of etching, anodizing, silk screening, and digital printing to create distinctive and durable identification solutions. Our commitment to excellence is reflected in every meticulous detail, ensuring that each name plate meets...

100 years of identification products for industry. DNPE meets any quality, durability & cost requirements with a full range of art & manufacturing capabilities. ID products include name plates, metal tags, custom decals, overlays, control panels, logo & barcode plates, UID tags, ASME plates, instruction plates, scales & dials, etc., utilizing aluminum, brass, MetalPhoto, stainless steel & vinyl.

Founded in 1923, Metal Marker Manufacturing is a manufacturer of name plates, custom metal tags, decals, metal photo products, and more. Numerous applications and industries have benefitted from our products, such as military, aerospace, and commercial. All products are made in the USA. With our ISO 9001 & AS9100 certification, our customers can be assured that they receive products of the...

At NFI Corp., we have been delivering quality nameplates since 1957. Our employees worldwide are dedicated to ensuring our customers’ deliver their high quality products to market, faster. Not only are we a customer driven company, but we strive for accountability and teamwork, we are committed to success and embrace change. For your next membrane keypads, call us today!

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Engraved Nameplate Manufacturers

In office settings, nameplates are used to indicate suite or room numbers, the occupant of an office and company names. Depending on the level of a company's investment in its image, it can choose nameplate materials ranging from inexpensive plastic to extravagant gold and even marble. Professional companies, private offices and institutions like colleges tend to make the most use of expensive nameplate materials.

On factory or warehouse floors, inexpensive plastic or aluminum nameplates are much more common. Because they are more likely to become damaged or tarnished by impact or exposure to dirt or other contaminants, it is much more economical to use plastic, aluminum or other inexpensive nameplate material for use in industrial settings and as labeling for equipment.

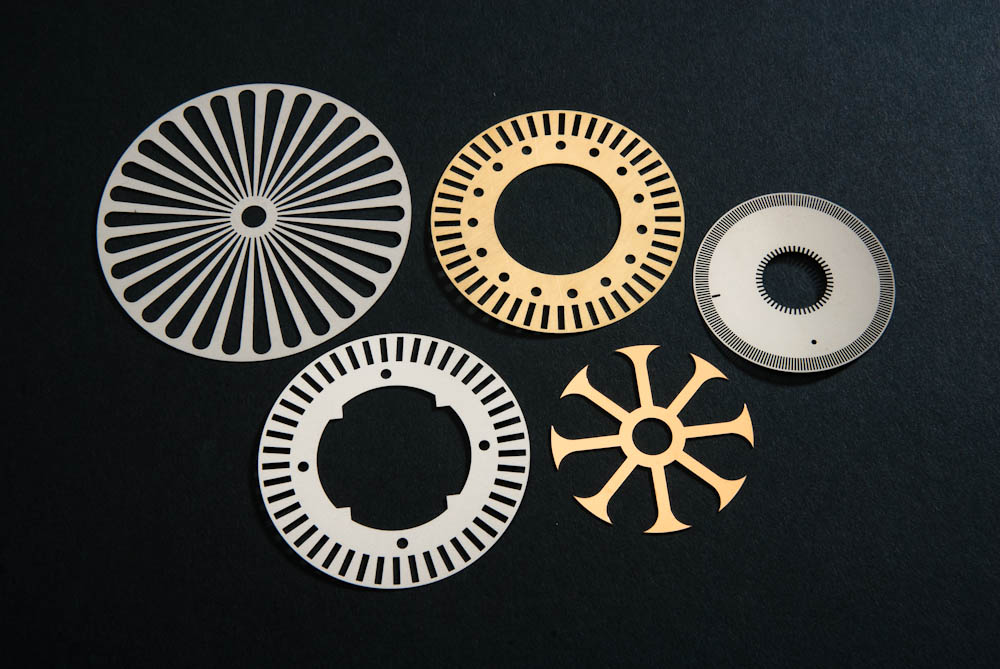

Nameplate engraving processes vary depending on the plate material. A thick bronze plate, for example, would not be engraved by the same machinery as would a thin plate of aluminum. Engravings can be made in many ways; different materials respond in different ways to each engraving method.

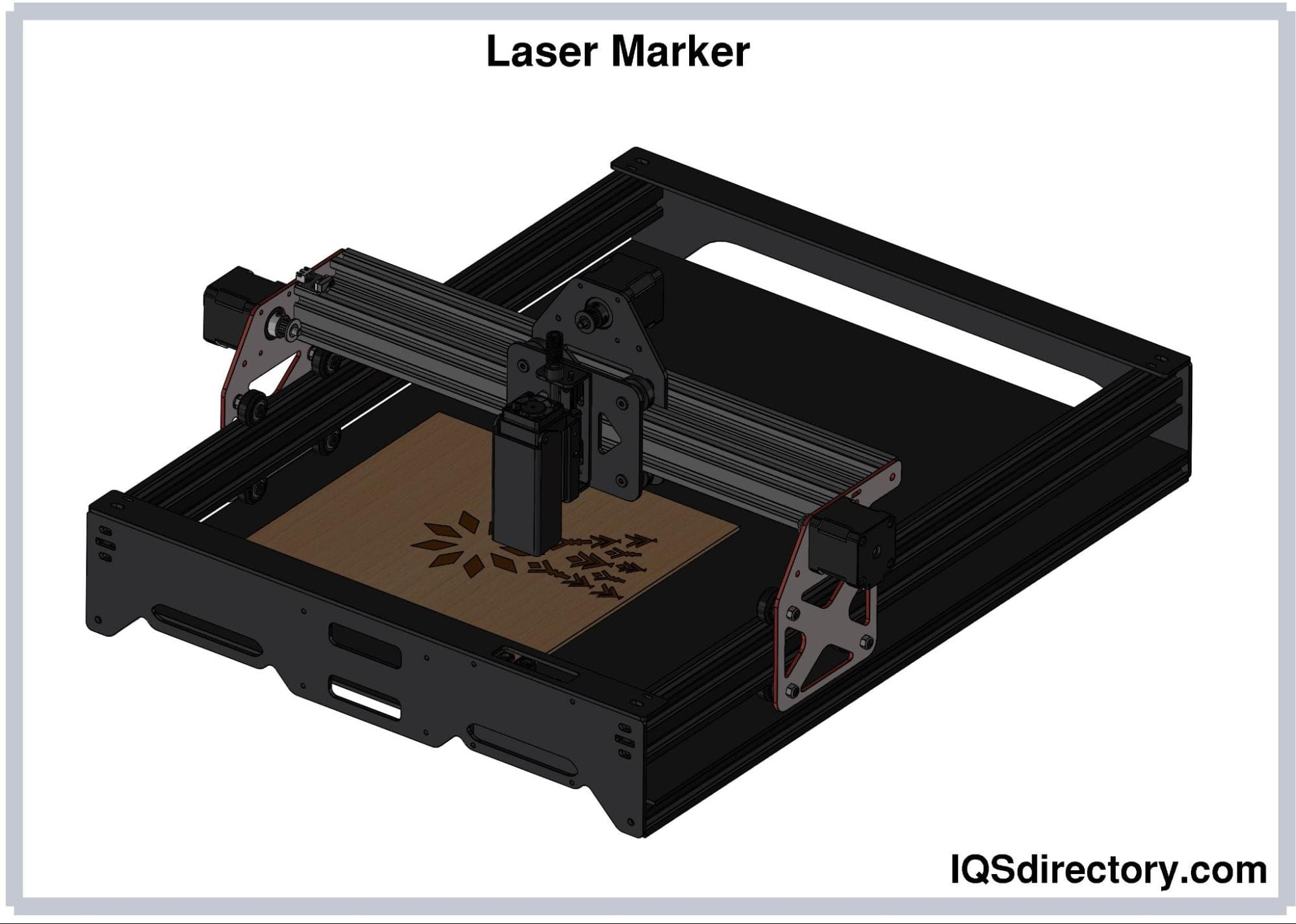

Laser engraving, for example, is an excellent precision engraving method that can create engraved markings of just a few micrometers in depth. However, a laser cannot cut as deeply into a surface as can a tool bit engraving method. Tool bit engraving methods involve physical contact between a surface and a tool bit. Tool bits can be made of diamond, tungsten-carbide and other hard materials that grind away areas of the surface to form symbols.

Titanium, zinc, brass, copper, stainless steel, aluminum and bronze are all common engraved nameplate materials. Engraved nameplates are chosen over other plate labeling methods because of their comparative longevity; an engraved word is not as vulnerable to degradation as is a painted word. For this reason, engraved nameplates can last much longer than other nameplate varieties.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services