Nameplates are tools of identification, usually fashioned in the form of signs or labels engraved or otherwise adorned with information. They are found all around, from office doors, to desks, to bridges. Read More…

Etched Metal Company takes pride in our expertise and precision in crafting exceptional name plates. With over 80 years of collective experience, we have mastered the arts of etching, anodizing, silk screening, and digital printing to create distinctive and durable identification solutions. Our commitment to excellence is reflected in every meticulous detail, ensuring that each name plate meets...

100 years of identification products for industry. DNPE meets any quality, durability & cost requirements with a full range of art & manufacturing capabilities. ID products include name plates, metal tags, custom decals, overlays, control panels, logo & barcode plates, UID tags, ASME plates, instruction plates, scales & dials, etc., utilizing aluminum, brass, MetalPhoto, stainless steel & vinyl.

Founded in 1923, Metal Marker Manufacturing is a manufacturer of name plates, custom metal tags, decals, metal photo products, and more. Numerous applications and industries have benefitted from our products, such as military, aerospace, and commercial. All products are made in the USA. With our ISO 9001 & AS9100 certification, our customers can be assured that they receive products of the...

At NFI Corp., we have been delivering quality nameplates since 1957. Our employees worldwide are dedicated to ensuring our customers’ deliver their high quality products to market, faster. Not only are we a customer driven company, but we strive for accountability and teamwork, we are committed to success and embrace change. For your next membrane keypads, call us today!

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of name plates, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes. Our team's goal is to bring you the best through our dedication to quality and our constant pursuit of the latest technology. contact...

More Name Plate Manufacturers

Nameplates are not to be confused with name tags. The main difference between the two is the fact that nameplates are usually mounted on something, such as a wall, a car, or a sculpture, whereas nametags are usually affixed to a uniform or another piece of clothing. Also, nametags are rarely engraved. Likewise, nameplates are not the same thing as name plaques, which are larger than nameplates and are designed to communicate in-depth information.

Applications

Mostly, rather than using them to display extensive amounts of information, customers use nameplate products to convey information quickly and concisely.

Bits of information office/professional nameplates often offer include the contents of desks, the location of emergency exits, and directions in a building or outdoor setting. Some professional nameplates also include information on artwork and sculptures, such as authorships, titles, and origins.

Examples of information conveyed by personal nameplate products include the ownership of chests, suitcases, briefcases, trunks or space; and the name and title of an award recipient on a trophy, plaque, or memorial.

Examples of industrial nameplate information include labels, products information, machinery instructions, equipment warnings, etc.

Design

Production Process

There are a number of methods manufacturers can use to adorn nameplate products with their labels. These methods include laser engraving, mechanical engraving, screen printing, sub-surface printing, hot stamping, etching, embossing, and photo anodizing.

Laser engraving involves cutting into a nameplate with a laser beam. Manufacturers laser engrave nameplates when they’re looking for extreme precision or intricacy.

Mechanical engraving involves cutting into a nameplate and creating labels with a rotary tool.

Screen printing is a little more involved; the process consists of applying a photogenic stencil to a piece of tightly stretched, porous polyester or another mesh, through which enamel colors are forced. The stencil blocks the ink from touching the mesh where it sits.

Sub-surface printing is a form of printing that manufacturers do below the surface or on the back of a substrate. They use this method to create nameplate labels that need protection against harsh environmental conditions, such as UV exposure, salt air, and abrasion-causing elements and solvents.

Hot stamping is a dry printing method during which manufacturers press dry paint or foil into a metal or plastic substrate. The process is aided by high heat and a die, made of metal or rubber. The die presses down on the product and the paint or foil, which is placed in between them. Manufacturers often use hot stamping to impress nameplates with serial numbers.

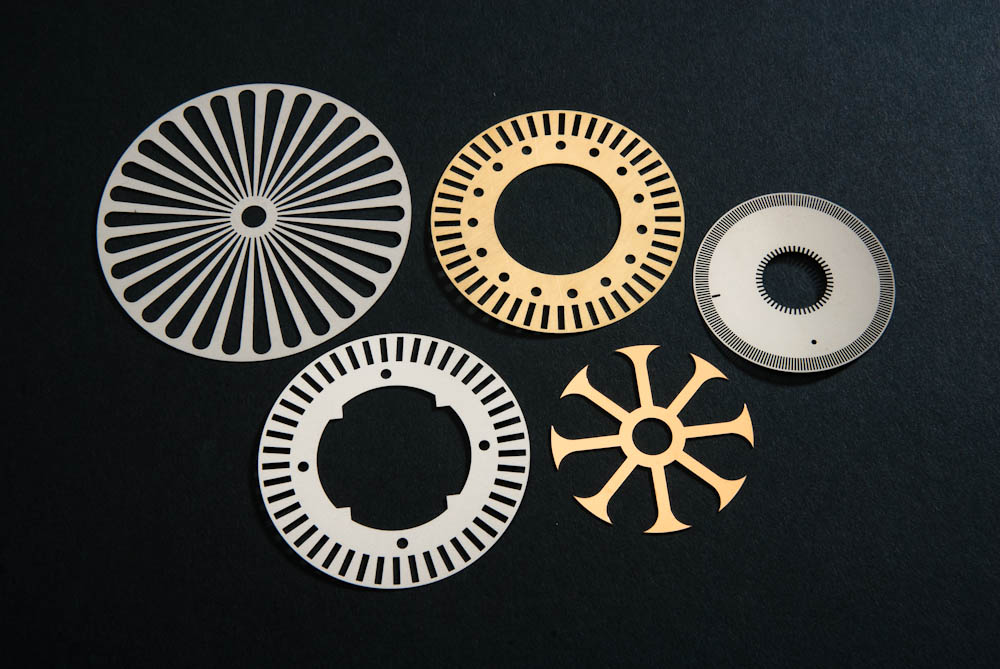

Chemical etching is a way that manufacturers engrave plates in order to make metal nameplates, like stainless steel, aluminum, or brass nameplates. To start the process, manufacturers first shield certain areas of the nameplate material with an acid resistant material, then expose the uncovered areas to a corrosive material. The uncovered areas of the metal nameplate correspond to a stencil design. The corrosive material engraves words onto the metal, per the design of the stencil, without harming the covered areas.

Embossing is a bit different from the other methods; it involves applying heat and pressure to metal plate as it squeezes through both a female and a male roller die. Each die is designed with the desired pattern for that particular nameplate.

Photo anodizing uses specialized aluminum sheets to print photo-quality images and words.

Materials

Nameplates may be made from many materials, and the prevalence of each material varies by industry. For example, nameplates made for the office tend to be made from plastic materials, wooden materials, or metals like aluminum and aluminum alloys, stainless steel, brass, zinc, or copper. Other materials that nameplate manufacturers may use include rigid PVC, vinyls, foils, Mylar®, MetalPhoto®, and more.

Considerations and Customization

When they make their products, nameplate manufacturers think about what you would like the nameplate to say, how you would like the nameplate to look, where you plan on putting the nameplate, how many nameplates you would like, and any applicable standard requirements.

Based on those considerations, nameplate suppliers can provide you with virtually any nameplate design. Design extends to things like name plate size, nameplate capacity, nameplate material, nameplate word font, nameplate mounting style, and nameplate weight. Custom nameplates are easy; in fact, all nameplates, by virtue of their purpose, display some level of customization, whether that be individualized messages, labels, or instructions.

Types

Office nameplates announce the contents and occupants of offices and desks. They typically only have one or two lines of information; usually, this information is a name and a job title. Types of office name plates include desk name plates, wall name plates, and door nameplates. All of these nameplates sit or are attached to the surfaces in their respective names.

Office signs are larger office nameplates , used to identify building spaces (waiting room signs, restroom signs, etc.), to offer instructions to staff/customers/visitors, or to give directions. Typically, office signs are attached to walls, not propped up on desks. Note: office signs affixed to doors may be called door signs or door name plates.

Industrial nameplates are those nameplates placed around industrial facilities to label equipment and specific workpieces. Industrial workpieces mounted on equipment are often also called equipment nameplates. Industrial nameplates are usually made out of durable materials like stainless steel. Stainless steel nameplates are especially desirable in those industrial applications that take place outside or in demanding settings.

Graphic overlay nameplates are name plates that feature embossing, transparent window displays, and selective texturing. Generally, they are resistant to both corrosion and chemicals. Most often, customers purchase them to place them over, or overlay, LEDS, windows, switches, or control panels.

Digital nameplates contain more than just visual information. Rather, they contain information that links to digital tools, such as customer support, product pages, etc. Examples of this information include serial nugs, tags, and a variety of alphanumeric characters. To access this information, users must simply scan the nameplate. Digital nameplates increase the usefulness of product nameplates without requiring manufacturers to physically add information onto the nameplate. Most often, manufacturers chemically engrave digital nameplates. This is because engraved information remains legible and scannable for a longer about of time.

Number plates are plastic or metal nameplates that help identify vehicles. You probably know them as license plates.

Gold nameplates, the most expensive name plates of all, are used both in the office and in institutions. For example, they are likely to be mounted on paintings, display cases, plaques and doors in museums, universities, cathedrals, and the offices of highly lucrative businesses.

Wooden name plates are, as one of would assume, name plates made from wood. Most often, people purchase wooden nameplates to hang on the door of a child’s playroom or bedroom. The nameplates may say the child’s name, or they come in whimsical shapes, such as animal shapes. Wooden nameplates are best for these applications because wood is safer than other nameplate materials, it is less expensive to produce, and children or parents can paint them. Those nameplates that fall into another category, personal nameplates, are more often made from wood; wood is safer and less expensive to produce for their largest market, children.

Bronze nameplates are usually used as office nameplates on desks of office higher-ups. They are among the most expensive office nameplate varieties.

Aluminum nameplates are among the least expensive nameplates available. As such, aluminum nameplates are much more widely used than many other types of nameplates. They are also popular because aluminum is lightweight and corrosion resistant. Aluminum nameplates are found on consumer products, like lawn mowers and washing machines, where they offer instructions for operations and identify risks of use; they are also found in large buildings, where they identify offices.

Plastic nameplates are still less expensive than aluminum nameplates, and also demand the least amount of maintenance.

Brass nameplates are designed to adorn something outside, such as building fronts or outdoor statues. Manufacturers like to use brass for tasks like these because the metal is so aesthetically pleasing. They are often made from brass that has been coated with a layer of weather-resistant chemicals. This treatment keeps the brass from tarnishing.

Advantages

Nameplates offer those who purchase them a wide range of benefits. First, of course, they help identify people, offices, work areas, and equipment. Because of this, they make workplaces more organized, more efficient, and easier to navigate. In addition, they provide people with a very tangible sense of belonging at their workplace.

Accessories

Nameplate manufacturers offer a number of useful accessories to go along with their main products. Primarily, these accessories have to do with physical support and adhesion of the nameplate. Examples include wall mount adhesives, wall hanging chains, pins, hooks, hangers, nameplate frames, nameplate holders, snap on nameplate label holders, and nameplate inserts.

Installation

Users can mount nameplates using one of three methods; they can fasten them, they can hold them with adhesives, or they can support them with another structure.

Fastening, though pretty simple, is still the most involved process. To fasten nameplates in place, users must drill the nameplates with holes, mount them where they would like them to go, and then insert into the holes screws, pins, nails, or another fastener type. Note that some nameplates may come with pre-drilled holes.

Adhesive coatings are available for purchase at the local hardware store, or customers can purchase them directly from their nameplate supplier. The important thing is to choose the adhesive with capabilities that match the environment in which nameplate will reside.

Nameplate supports are most often plastic, wooden, or metal stands. These are most useful with heavy office and desk nameplates.

Standards

Nameplate standards are not generally as strict or as expansive as the standards upheld for the vast majority of industrial items. If you run into standard requirements for nameplates, it will likely be for industrial nameplates or equipment nameplates only. Examples of standards those may need to meet include those related to environmental tolerances and print life. Nameplates that typically have more stringent requirements include those mounted on equipment like centrifugal pumps, generators, and electric motors.

If you plan on purchasing motor nameplates for use in the USA, your nameplate must meet the standards of NEMA (the National Electrical Manufacturers Association). NEMA requires that all motor nameplates list certain information, including the manufacturer type, the rated voltage, the rated frequency, the rated full load RPM, the rated temperature rise (insulation system class), the full-load current, the time rating, the number of phases, the horsepower, the frame size, the service factor, the design letter, the locked rotor code letter, and the efficiency.

Things to Consider

If you are in the market for a quality nameplate, or several quality name plates, you need to work with an experienced manufacturer. The right manufacturer will make sure your name plates are well made and professional (unless you are commissioning name tags for children, in which case, they will make them as whimsical as you’d like). They will also make sure all the information on them is accurate, and they will deliver them on time.

Find a trustworthy nameplate manufacturer by checking out those we have detailed on this page. You will find individual profiles wedged in between our info paragraphs. Before looking them over, we recommend you take some time to put together a specifications list. This should cover all aspects of your application, from your request volume to your budget. This this will not only focus your search, but it will also focus your conversations after you’ve identified your potential suppliers.

Laser Cutting

Laser Cutting Lasers

Lasers Marking Machinery

Marking Machinery Metal Etching

Metal Etching Name Plates

Name Plates Labeling Equipment

Labeling Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services